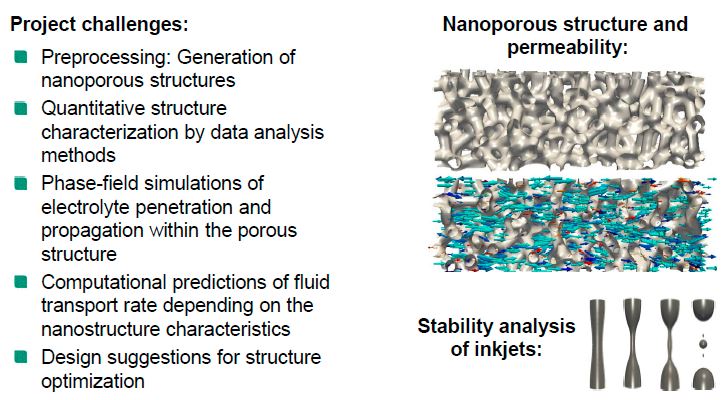

Computational design of nanoporous structures for printed electronics

Within the Virtual Materials Design initiative, 3D phase-field simulations of fluid transport driven by wetting and capillary forces are employed to predict the electrolyte penetration and propagation in porous semiconductor nanostructures. The simulation results serve as a basis for computationally designing optimal porosities of the 50-100 nm thick layer of semiconductor nanostructures in printed electronics' devices.

For preparation of the simulations, we use 3D computer tomography data of the nanostructures to initialize the computational domain. To transfer the information of real structures, suitable programming interfaces are developed. Furthermore, we algorithmically design porous nanostructures with varying, controlled and tailored pore size distributions (porosities) in order to optimize the nanostructures with respect to electrolyte transport. By applying data analysis techniques based on principal component algorithms, we quantitatively characterize the considered nanoporous structures in order to derive predictions of the fluid propagation depending on structural properties.

The phase-field method with novel extensions to capture the correct physical contact angle conditions of wetting processes on structured surfaces will be employed to investigate the penetration of electrolyte fluid in the designed nanoporous structures. The model and simulation framework are capable to predict the fluid transport solely driven by capillary forces. In simulation studies, we systematically quantify the electrolyte transport for both, free as well as constraint surface layer conditions. The simulation results will predict the correlations of fluid transport rate and the nanostructure characteristics. From these predictions, we will derive design suggestions to optimize the structure of the nanoporous layer.

As long-term research perspectives, we propose to study spinodal decomposition of block-copolymers and the resulting microstructure formation by phase separation using a combined Cahn-Hilliard - Navier-Stokes model. The simulations will be able to describe the influence of processing conditions (temperature, composition, ... ) on the properties of the nanostructures. Another direction for future work is the simulation of nanoparticle sintering including effects such as wetting, evaporation, neck formation and different temperature profiles resulting in characteristic pore size distributions.

Dr. Fei Wang is working with Prof. Britta Nestler on this project.